The Swiss made Thorens TD-124 is one of the most desired and famous turntables ever made. A properly set up TD-124 can outperform far more expensive current day turntables. Proper set up is not easy though and requires some mastery of the technique. It was introduced in 1957 and in production up until 1965 when the MK2 version was released. In fact, Thorens built its global reputation for excellence with the TD-124 from the late 50’s through the mid 60’s. Robert Thorens the head engineer at the company, based in Sainte-Croix Switzerland, spearheaded the design of the turntable which incorporated many new and innovative design features. The TD in the name stands for “tourne-disque” in French which, in English means “record turner”.

The TD-124 turntable was so superior that other hi end audio companies such as Bang & Olufsen and Tandbeg used a rebranded TD-124 in their turntable offerings. The early Bang & Olufsen Beogram 3000 turntable is an example of this. It was part of B&O’s high end Beogram 5000 Professional system and incorporated the TD-124 turntable which still even had the Thorens logo near the speed change control.

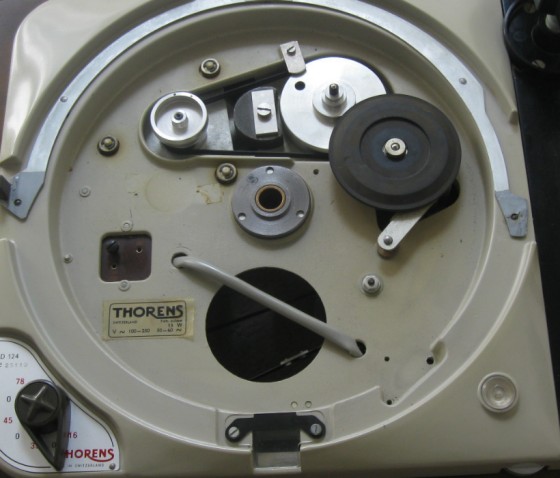

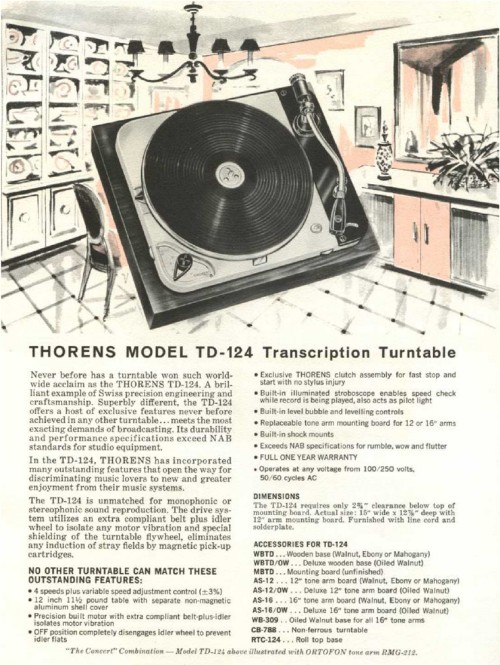

One of the main features of the TD-124 was its use of both a belt and and idler to drive the table. Other turntables such as the Garrard at the time used a stepped pulley on the motor to drive an idler wheel which in turn drives the turntable. This, of course, worked fine but Thorens used a belt from the motor to a separate stepped pulley, mounted to the chassis, which then drove the idler wheel. This added another dimension to isolate vibration from the motor to the platter. The stepped pulley allowed the table to run at 4 different speeds of 16 2/3, 33 1/3, 45 and 78 RPM all of which are adjustable by +/- 3% through a pitch control adjustment.

The 15″ wide x 12 7/8″ deep TD-124 has a 12 inch rather heavy 9.5 pound (4.3 Kg), and sometimes more, cast iron platter which is spun by a 10 watt motor which some see as the one weakness of the turntable. While 10 watts is a fairly strong motor the Garrard utilized a 16 watt motor. Still, Thorens motor design was novel and probably superior to any other at the time. The original motor was the E50 which when operating properly should get the platter up to full speed within 3/4 of a revolution of the table. When the motors go bad or need service the speed will take far longer to reach max or not reach max at all.

Kits are available to rebuild the motors as well as some technicians who will do it for you. Thorens ran out of the E50 motors in the late 70’s and replaced it with a different motor (Pabst) that requires slightly different mounting then the original.

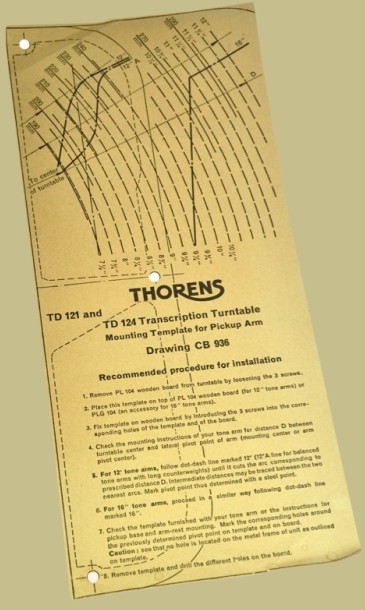

Thorens shipped the TD-124 without a tonearm but, once they reached the dealer, they were often fitted with the ESL 1000 Gyro Balance tonearm. Other tonearms used were the Ortofon RMG 212 and SME 3012. The turntable has a replaceable tonearm mounting board allowing the use of varying sizes of tonearms.

Here are some of the accessories available for the Thorens TD-124 when in production:

- WBTD – wooden base (walnut, ebony or mahogany)

- WBTD/OW – deluxe wooden base (oiled walnut)

- MBTD – mounting board (unfinished)

- AS-12 – 12″ tone arm board (walnut, ebony or mahogany)

- AS-12/OW – deluxe 12″ tone arm board (oiled walnut)

- AS-16 – 16″ tone arm board (walnut, ebony or mahogany)

- AS-16/OW – deluxe 16″ tone arm board (oiled walnut)

- WB-309 – oiled walnut base for all 16″ tone arms

- CB-788 – non-ferrous turntable

- RTC-124 – roll top base

If you’re looking to purchase a Thorens TD-124 be prepared to pay a hefty price. Restored tables sell fairly regularly for over $1500.00 depending upon the tonearm and other accessories. Even units in need of restoration go for around $800.00 to $1000.00. If you want to buy one to restore keep in mind that some parts are becoming difficult to find. As I mentioned above the motors can be refurbished and some of the other parts are being reproduced on a small scale so a restoration can be done. But, once you’ve purchased the parts and/or paid someone to do the restoration you’ll have quite an investment in the turntable. On the bright side, it’s not an investment that is likely to go down in value though. Be sure to check for problems such as:

- Slow or varying motor speed

- Dry idler

- Dried or cracked suspension rubber pods

- Dried out or cracked belt

- Bad audio cables which can introduce hum

Once you have a properly working TD-124 you won’t need to look for another turntable for a long time, if ever, because you’ll have one of the best turntables ever made.

I have become versed in the correct methods employed by Thorens engineers. While tables from schopper are pretty and run just fine, they are not worth $5,000.00 fine. In my opinion the tables restored by STS are far superior. The technics used are exactly as the original ones were meant. The ebay seller sumthinsilly charges a much fairer price for superior craftsmanship. His custom platters, idlers and bearings are better and closer to factory. Not just shiny. I put the $3299 table above the $5000 10 Nano Farad (nF) at 220 V was the original value but I’d replace that with one of a higher voltage rating (400V) totable any day. I have a $12,000 creation of his. You get what you pay for.

I was giving a thorens td 124 /11. I had no idea at the time it was considered a vintage machine until I looked it up on the internet.I really have no use for it but don’t know the best way to sell it. Any suggestions?

Do you have a tonearm counter weight for the Thoren 124 turntable?

Hello,

I recently acquired a TD124 as my second table. While the table is immaculate and well-serviced by competent techs, it still suffers from more speed variation (when fully warm and “stable”) than my table which is controlled by a pulse width modulator power supply. Has anyone worked on a power supply for these tables that would assure a constant and continuous wave form to feed the E50? Or some other approach?

Thanks