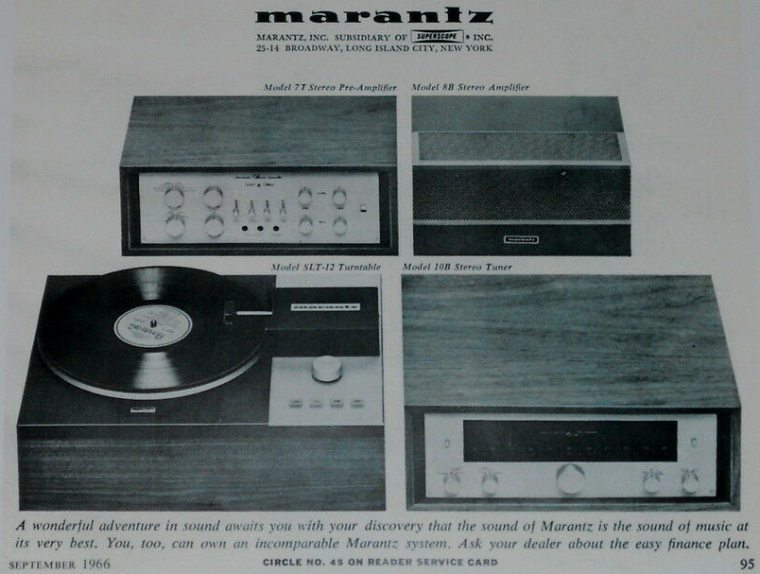

This interesting turntable is the Marantz SLT-12. It was introduced in 1963 at a time when Saul Marantz and Sidney Smith were still with the company. It retailed for roughly $295.00. At the time, Marantz was still a fairly small company based in New York. The development of the SLT-12 and the Marantz Model 10 tuner in the early 60’s was expensive and put financial pressure on Marantz until Superscope came in and purchased the company in 1964. The SLT-12 was on the market possibly up until 1971.

The SLT-12 acquired a somewhat bad reputation early on as the adjustments required to get it to play properly seemed complicated to the average user used to a standard tonearm. So, they have a reputation of being temperamental. However, if they are setup correctly they will perform excellently.

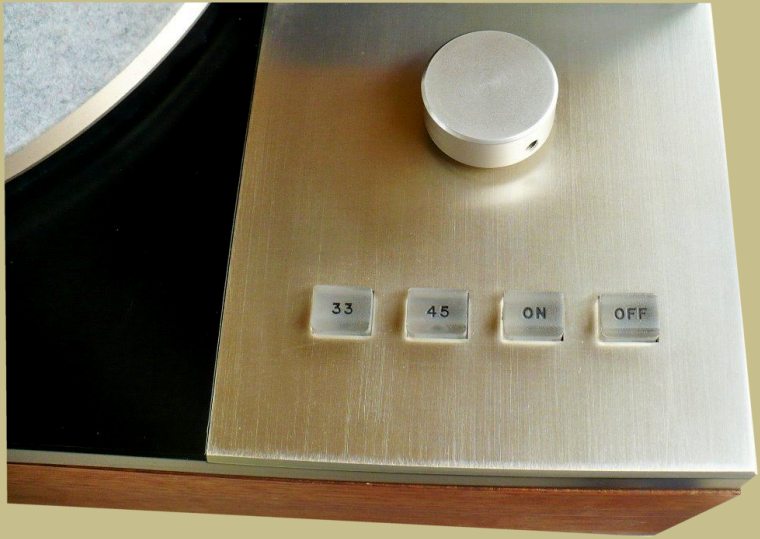

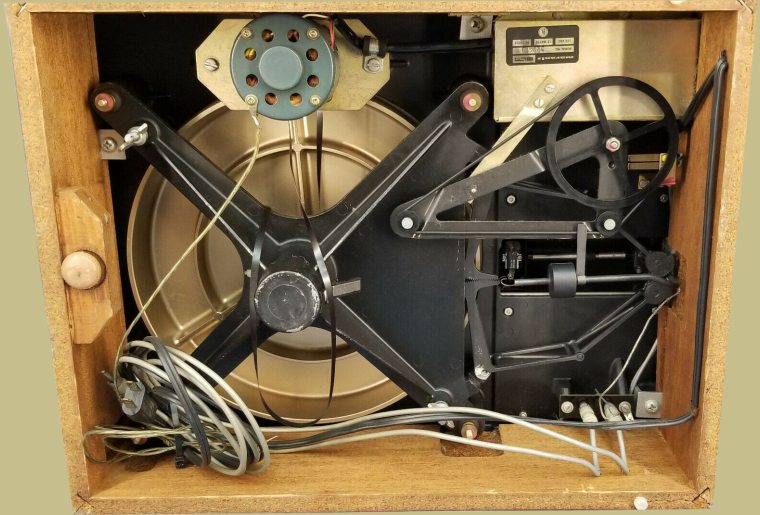

The SLT-12 is a two speed table and it is completely mechanical. No IC chips. The tonearm is an early Linear Tracking design with some interesting engineering. Technically it is a passive linear tracking mechanism which means it has no motion assist (servo) or such to move the tonearm. It is all passive. The tonearm is activated by two gears and some articulated arms which all have pivot points with precision ball bearings. So, the tonearm’s lateral movement is determined solely by the grooves in the record (when it’s working properly).

There is no counterweight on the tonearm but there is one attached to an articulated arm below it. As the end of a record is reached the counterweight enters a magnetized area and is pulled downward. This causes the tonearm itself to move upward and disengage from the record. There is also a circuit that will mute the signal whenever the arm is raised. Brilliant. Adjustment of the tonearm is done via the large knob. Just press the knob, then turn it left or right until the correct adjustment is made.

Marantz claimed that adjusting the tonearm was so easy a child could do it. That might have been true assuming everything was set up properly in the first place. Then, a quick turn of the knob might do the trick. Unfortunately, if the platter or base was out of balance or an aftermarket mat was used with a different thickness then more intricate adjustments might be needed.

The original mats were made of polyurethane foam and have long since deteriorated. When placing a new mat on the SLT-12 an adjustment may be required if it is thinner or thicker than the original OEM mat.

In the mid 1960’s Marantz ads showed the SLT-12 paired up with the 10B tuner, 8B amplifier and 7T pre-amp.

There is a model SLT-12U turntable as well but the only difference between the two models is the cartridge. The SLT-12 has a dedicated Shure cartridge that was made to Marantz specs but the SLT-12U has a 1/2″ universal mount so therefore has the ability to accept different cartridges. When purchasing an SLT-12 be sure that the original cartridge mount is present. They are extremely hard to find so if it’s missing then then there is no way to mount a cartridge.

The platter on the SLT-12 is a hefty 12 pounds (5.8kg) and is belt driven via a hysteresis-synchronous motor. There is a bubble level inside the tonearm housing that can be used to level the base and platter but it is not very reliable so if you’re setting up an SLT-12 it might be better to use a round bubble level. Leveling is essential to getting the SLT-12 to operate properly. The tonearm will not move freely without proper leveling which can result in damage to the stylus or record.

The Marantz SLT-12 came with a walnut wood base and an optional dust cover. The dust covers are nearly impossible to find these days and extremely pricey if you do find one.

Overall, the SLT-12 is a great turntable with one caveat. It has to be operating properly. They are temperamental but can be fantastic when set up properly. Unfortunately parts are difficult to come by so any repairs or replacements can be expensive. If you’re into interesting audio engineering, and are up to the task of tinkering with it to get it to work properly, then the SLT-12 or SLT-12U might be worth a look.

Hello. The SLT was the product that ended the company. The wife cooking in the kitchen caused enough grease in the air to gum up the 16 ball bearings and gears. Inertia and stiction brought them all back to the factory for skipping. Joe Tushinsky then bought the name for peanuts and transferred mfg to orient. Sad end to the early “Rolls Royce” of HiFi. Paul S aka Soundman

Purchased 2 or 3, mid ~ 70’s, one worked well. Excellent! Could hear details that weren’t apparent on other good set ~ ups. Very good design as it tracks exactly as the LP was, “cut,” eliminating distortion, particularly, “inner groove.” Best design, in my opinion. In fact, for a time, Shure had an advanced cartridge which had a small brush. If you set the tracking force at two grams, as specified, the brush would relieve the stylus pressure, “lift up the cartridge,” one gram, so that the stylus tracking force on the record was actually: one gram. The total was the proper tracking force for arm operation. [I’d recommend a total tracking force of two and one quarter, to two and a half grams, so that the actual stylus pressure on the disc is one and one quarter, to one and a half gram. And / or: Read the cartridge manufacturer’s specifications}. There were other, “Radial Tracking,” turntables. Radio Shack, Tandy, had one, which operated via a small, slowly revolving tube at the back of the turntable. This tube caused the are to, “right itself,” when the arm went out of exact position. Also purchased a Sony turntable which has a sensor at the back, assisting the straight tone arm to be in proper position. This Sony was, “chip, small computer controlled.” It, therefore, was, at times, “finicky,” didn’t seem to work well, perfectly. But when it did, work as it was supposed to, it was excellent! {Had to start a 12″ disc from the outside, the beginning, couldn’t go directly to an inner track.} All of the these radial arm turntables, other than the Marantz, were criticized for actually tracking in a bit of a, “Duck Walk;” in that, as the cartridge tracked the revolving disc, the front of the arm would move, toward the left, & the mechanism would then have to make the arm be perfectly centered; at times, this procedure may cause a bit of an, “overshoot, overcorrection.” These designs worked, from, “pretty well,” to excellently! I suppose that it depends on your interest in new designs, approaches, trying something different {which may, or may not, as we know, be an improvement to what you already have! Good Luck!}